limitations of brinell hardness test and why|brinell hardness testing method : solutions l Longer testing time: Generally speaking, the Brinell test requires more time . Caps are fabricated from a special formula resistant to the effects of temperature and steam in autoclaving and are provided with a Polytetrafluorethylene (PTFE) interface firmly bonded to the glued-in rubber liner, providing a sure and .

{plog:ftitle_list}

Autoclave, also known as steam sterilizer, is the most effective machine for the sterilization of lab equipment, water, or media. The machine uses steam under pressure to kill bacteria, viruses, and spores present in/on .

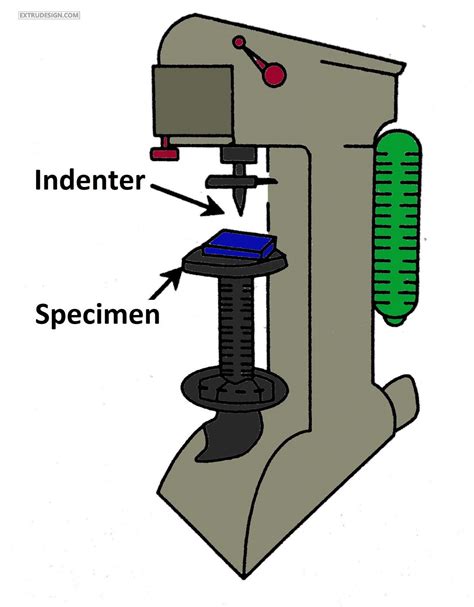

The Brinell Hardness Test method is used to evaluate the hardness of the .What is Brinell Hardness Test? The Brinell Hardness Test is a way to measure how hard a material is by pressing a hard ball into it and seeing how big the dent is. What are the advantages and disadvantages of Brinell Hardness Test

Understanding the limitations of the Brinell Hardness Test is essential for mitigating potential errors and ensuring the reliability of hardness measurements. l Longer testing time: Generally speaking, the Brinell test requires more time . Brinell hardness testing has its limitations, however, including the need to use a selection of different-sized indenters depending upon the material under test and, sometimes, it’s not suitable for testing very small components.In the Brinell Hardness Testing, the hardness of a metal is determined by measuring the permanent indentation size produced by an indenter. The Brinell Hardness Test method is the most commonly used hardness measurement .

brinell hardness testing procedure

The Brinell test has several limitations; 1. Cannot be used on soft materials. 2. The test may .Brinell testing of a material with different ball diameters and test forces must be conducted within the same force-diameter index ("Brinell test procedure") in order to enable direct comparison of the measured hardness values. EN ISO 6506-1 is a European standard that specifies the requirements for .

lame de terrasse bois autoclave classe 4

In this article, we have seen the Brinell hardness test and its two different methods – Standard and Non-Standard Brinell hardness tests. Also, discussed its advantages, disadvantages or limitations, and applications.The Brinell Hardness Test method is used to evaluate the hardness of the object, especially for non-ferrous metals, cast irons, and steel products at the higher strength ranges and aluminum and copper alloys at lower strength ranges. But it cannot measure extremely hardened materials like .What is Brinell Hardness Test? The Brinell Hardness Test is a way to measure how hard a material is by pressing a hard ball into it and seeing how big the dent is. What are the advantages and disadvantages of Brinell Hardness TestUnderstanding the limitations of the Brinell Hardness Test is essential for mitigating potential errors and ensuring the reliability of hardness measurements.

brinell hardness testing method

l Longer testing time: Generally speaking, the Brinell test requires more time than Vickers or Rockwell methods for determining hardness. l Requires more maintenance: Regular replacement of the. Brinell hardness testing has its limitations, however, including the need to use a selection of different-sized indenters depending upon the material under test and, sometimes, it’s not suitable for testing very small components.In the Brinell Hardness Testing, the hardness of a metal is determined by measuring the permanent indentation size produced by an indenter. The Brinell Hardness Test method is the most commonly used hardness measurement technique in the industry.

The Brinell test has several limitations; 1. Cannot be used on soft materials. 2. The test may not be valid for thin specimens. The minimum thickness is about 0.313 in. 3. The test is not valid for case hardened materials. 4. The test should not be conducted too close to the edge of material. 5.Brinell testing of a material with different ball diameters and test forces must be conducted within the same force-diameter index ("Brinell test procedure") in order to enable direct comparison of the measured hardness values.

EN ISO 6506-1 is a European standard that specifies the requirements for metallic materials' Brinell hardness testing. It outlines the testing method, equipment, calibration, and procedures for determining the Brinell hardness of metallic materials using test forces between 1.96 N and 29420 N. In this article, we have seen the Brinell hardness test and its two different methods – Standard and Non-Standard Brinell hardness tests. Also, discussed its advantages, disadvantages or limitations, and applications.

The Brinell Hardness Test method is used to evaluate the hardness of the object, especially for non-ferrous metals, cast irons, and steel products at the higher strength ranges and aluminum and copper alloys at lower strength ranges. But it cannot measure extremely hardened materials like .

What is Brinell Hardness Test? The Brinell Hardness Test is a way to measure how hard a material is by pressing a hard ball into it and seeing how big the dent is. What are the advantages and disadvantages of Brinell Hardness Test

Understanding the limitations of the Brinell Hardness Test is essential for mitigating potential errors and ensuring the reliability of hardness measurements.

l Longer testing time: Generally speaking, the Brinell test requires more time than Vickers or Rockwell methods for determining hardness. l Requires more maintenance: Regular replacement of the. Brinell hardness testing has its limitations, however, including the need to use a selection of different-sized indenters depending upon the material under test and, sometimes, it’s not suitable for testing very small components.In the Brinell Hardness Testing, the hardness of a metal is determined by measuring the permanent indentation size produced by an indenter. The Brinell Hardness Test method is the most commonly used hardness measurement technique in the industry.The Brinell test has several limitations; 1. Cannot be used on soft materials. 2. The test may not be valid for thin specimens. The minimum thickness is about 0.313 in. 3. The test is not valid for case hardened materials. 4. The test should not be conducted too close to the edge of material. 5.

lame de terrasse douglas autoclave

Brinell testing of a material with different ball diameters and test forces must be conducted within the same force-diameter index ("Brinell test procedure") in order to enable direct comparison of the measured hardness values.

brinell hardness testing machine diagram

lame de terrasse pin autoclave brico depot

lame de terrasse pin autoclave classe 4 prix

Large stainless steel autoclave tray, dental sterilization cassette. Made of stainless steel wire-frame mesh, reinforced with stainless steel rods for heavy duty use. Used for sterilization or storage.

limitations of brinell hardness test and why|brinell hardness testing method